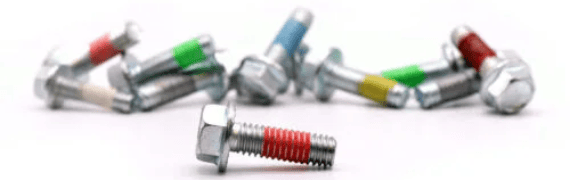

PAAC’D® Fasteners

When you need PAAC’D® Fastener options, there are two broad categories to consider: anti-vibrational sealants and threadlockers. Our line of Loctite® patch products contains both threadlockers and anti-vibrational sealants and can be applied to most fasteners.

Loctite® Threadlockers and Vibra-Seal Thread Sealants

Pre-applied threadlockers are adhesives that bond the fastener’s threads together by mating the threads and curing hard like an epoxy. Pre-applied thread sealants are non-curing, so they don’t get hard or brittle and act as a (relatively) soft wedge that creates a seal and can also cushion vibrations.