What Are Shoulder Screws?

Choosing the right type of fastener makes all the difference in the success of assembly and construction projects. Shoulder screws are durable, strong screws built for assemblies with rotating parts.

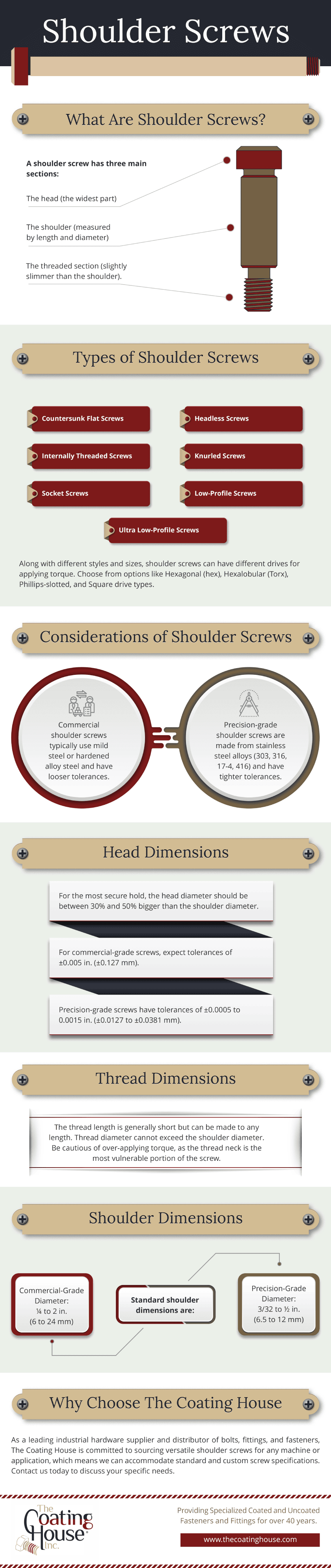

A shoulder screw has three main sections: the head (the widest part), the shoulder (measured by length and diameter), and the threaded section (slightly slimmer than the shoulder). When the shoulder screw is installed, the threaded section is embedded fully in the assembly, and the shoulder acts as a shaft for bearings, a guide for sliding elements, an axle for rolling components, or a mounting pin. The head helps hold the rotating piece in position.

As a leading industrial hardware supplier, The Coating House supplies clients with a wide variety of standard and custom-sized shoulder screws made from different metal alloys, with different finish options, and with different length and diameter specifications for the shoulders. Our most popular shoulder screws are made from stainless steel or heat-treated alloy steel. Each screw can have a plain or black oxide finish, and we also offer value-added bead blasting, Zinc/Magni plating, and thread-locking patch services to create premium shoulder screws. All shoulder screws meet ASME B18.3 specifications.

Types of Shoulder Screws

Shoulder screws are incredibly versatile because they come in a wide range of sizes and styles. At The Coating House, we can provide both imperial and metric sizes with different shoulder length and diameter options. Some of the most popular types of shoulder screws we manufacture are:

- Countersunk Flat Screws

- Headless Screws

- Internally Threaded Screws

- Knurled Screws

- Socket Screws

- Low-Profile Screws

- Ultra Low-Profile Screws

Along with different styles and sizes, shoulder screws can have different drives for applying torque. Choose from options like Hexagonal (hex), Hexalobular (Torx), Phillips-slotted, and Square drive types.

Considerations of Shoulder Screws

There are many different variables to specify when you’re ordering shoulder screws, as each specification can influence how suitable the fasteners are for your application. The smooth shoulder section is the main differentiator from other types of screws like machine and cap screws, so it’s important to know your precise requirements.

The key measurements are the shoulder diameter and shoulder length. The shoulder diameter is the diameter through the smooth shoulder section, which will generally be smaller than the head and slightly larger than the threaded bottom portion. The shoulder length specifically refers to the length of just the shoulder portion of the screw. So if you have a shoulder screw with a 1″ length, the shoulder portion will be 1″, and the entire screw (the head, shoulder, and threaded portion) will be longer.

We can provide both commercial-grade shoulder screws and precision-grade shoulder screws. Commercial screws typically use mild steel or hardened alloy steel and have looser tolerances, while precision-grade screws are made from stainless steel alloys (303, 316, 17-4, 416) and have tighter tolerances.

Head Dimensions

First, determine the right head dimensions for your application. Generally, shoulder screw heads resemble modified fillister heads, in which the head’s diameter (or length across) is twice its height. However, the shoulder screw head is mostly flat with a 30-50° chamfer around it, giving it slightly rounded edges.

For the most secure hold, the head diameter should be between 30% and 50% bigger than the shoulder diameter. For commercial-grade screws, expect tolerances of ±0.005 in. (±0.127 mm). Precision-grade screws have tolerances of ±0.0005 to 0.0015 in. (±0.0127 to ±0.0381 mm).

Thread Dimensions

The thread length is generally short but can be made to any length. Thread diameter cannot exceed the shoulder diameter. Be cautious of over-applying torque, as the thread neck is the most vulnerable portion of the screw.

Shoulder Dimensions

Standard shoulder dimensions are:

- Commercial-Grade Diameter: ¼ to 2 in. (6 to 24 mm)

- Precision-Grade Diameter: 3/32 to ½ in. (6.5 to 12 mm)

You can also choose custom diameters, and we can provide screws of any shoulder length (with measurements taken from under the head to the end of the shoulder).

Why Choose The Coating House

As a leading industrial hardware supplier and distributor of bolts, fittings, and fasteners, The Coating House is committed to sourcing versatile shoulder screws for any machine or application, which means we can accommodate standard and custom screw specifications. Contact us today to discuss your specific needs.