When you require a secure fastener for your product or assembly, captive screws offer a reliable, long-lasting hold. Named for the fact that they’ll stay “captive” within their holes, captive screws won’t fall out and get lost during installation or disassembly.

At The Coating House Inc., we specialize in supplying high-quality fasteners and fittings to a diverse client base. Captive screws are one of our many high-performance fastening solutions. Read on to learn more about these screws and their many benefits, as well as the various types we offer.

What Is a Captive Screw?

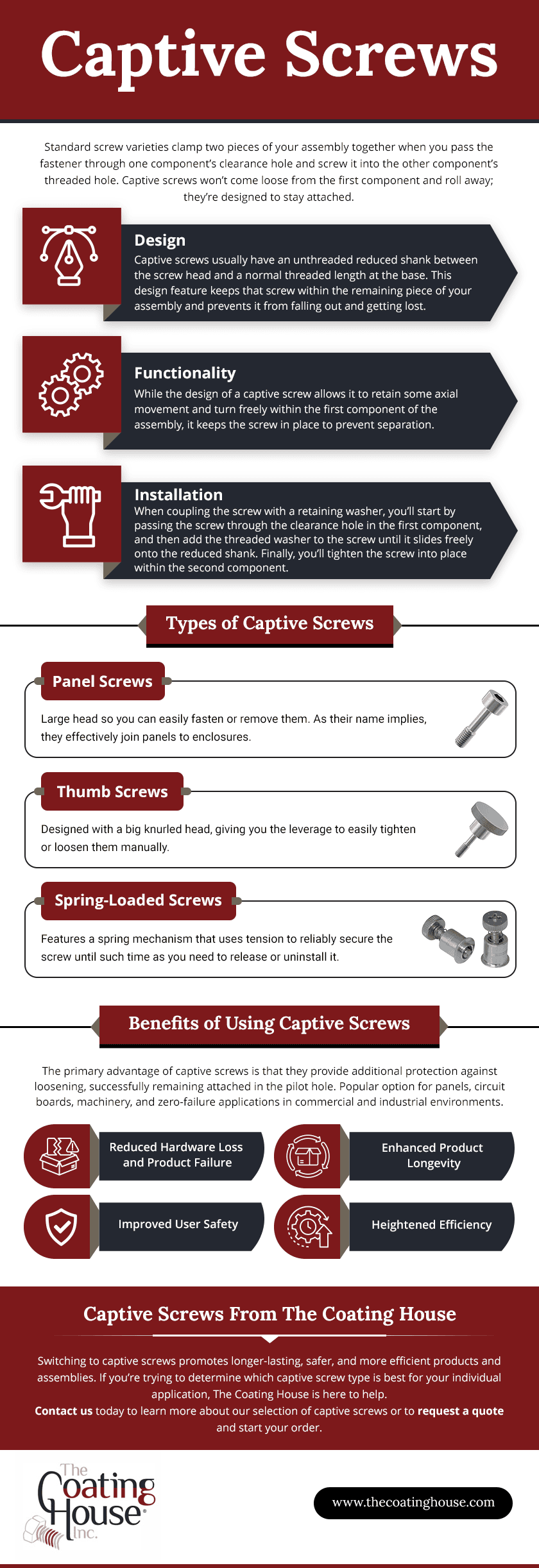

This specialized fastener type is similar to conventional screws. Standard screw varieties clamp two pieces of your assembly together when you pass the fastener through one component’s clearance hole and screw it into the other component’s threaded hole. Should you later remove that mating component, however, it’s here that captive screws differentiate themselves. Captive screws won’t come loose from the first component and roll away; they’re designed to stay attached.

Design

Captive screws usually have an unthreaded reduced shank between the screw head and a normal threaded length at the base. Even when a screw is loosened from the mating component, this design feature keeps that screw within the remaining piece of your assembly and prevents it from falling out and getting lost.

Functionality

While the design of a captive screw allows it to retain some axial movement and turn freely within the first component of the assembly, it keeps the screw in place to prevent separation. Your product or assembly will dependably remain intact, even when its screws are exposed to stress or vibration that might compromise conventional screws.

Installation

You have a few installation options with captive screws. If you choose to couple the screw with a retaining washer, you’ll start by passing the screw through the clearance hole in the first component, and then add the threaded washer to the screw until it slides freely onto the reduced shank. Alternatively, with a retaining flange, you’ll press the flange into the component first and then screw the fastener into the flange sufficiently that it meets the reduced-diameter portion of the screw. Finally, you’ll tighten the screw into place within the second component.

Types of Captive Screws

At The Coating House, we provide three main varieties of captive screws to suit the needs of our clients’ varied projects:

- Panel Screws. These screws typically have a large head so you can easily fasten or remove them. As their name implies, they effectively join panels to enclosures.

- Thumb Screws. Thumb screws are designed with a big knurled head, giving you the leverage to easily tighten or loosen them manually.

- Spring-Loaded Screws. This screw type features a spring mechanism that uses tension to reliably secure the screw until such time as you need to release or uninstall it.

Benefits of Using Captive Screws

The primary advantage of captive screws is that they provide additional protection against loosening, successfully remaining attached in the pilot hole. For this reason, they’re a popular option for panels, circuit boards, machinery, and zero-failure applications in commercial and industrial environments. Some of the specific benefits these screws provide include:

- Reduced Hardware Loss and Product Failure. With captive screws, you minimize the risk of losing screws and having to replace hardware. You can have confidence in your assemblies in the field without worrying about missing or loosened fasteners causing costly downtime with equipment repairs and reinstallations.

- Enhanced Product Longevity. This advantage also has the side benefit of helping products and assemblies last longer as the fasteners are designed not to fall out, degrade with age, or fail.

- Improved User Safety. As the fasteners are unlikely to come out unintentionally, their secure hold can enhance the safety of your assembly or equipment for users.

- Heightened Efficiency. Despite their firm fastening capabilities, captive screws are quite easy and quick to use, so they facilitate product assembly. Integrating them with electronic hardware like retainers, you can produce self-captivating fasteners that allow for loosening but won’t separate.

Captive Screws From The Coating House

Switching to captive screws promotes longer-lasting, safer, and more efficient products and assemblies. If you’re trying to determine which captive screw type is best for your individual application, The Coating House is here to help. Since 1980, our woman-owned company has been delivering fastener, fitting, and bolt solutions to help our clients reduce component failure and operational downtime in the field. Our coated, uncoated, and custom products have applications in everything from aerospace and automotive projects to electronic and medical equipment.

Contact us today to learn more about our selection of captive screws or to request a quote and start your order.